DOHC Engine Manual - Enginediy

DOHC Engine Manual - Enginediy

First of all, thank you for choosing our products. DOHC is a set of very precise in-line four-cylinder four-stroke engine parts. Before operating your engine, please read the "Safety Instructions and Warnings" and parts assembly part of this manual, and Strictly follow all the contents of this manual to familiarize yourself with engine control and other functions. In addition, please keep this manual in a safe place so that you can refer to it at any time when necessary.

1. ABOUT YOUR ENGINE

This is a model engine with fuel oil. Except for the scale, it is almost close to the real engine. Please remember that your engine is not a "toy". Because this engine has a large torque and speed, it may cause injury to you during use. Please do not modify or disassemble it without authorization. As a professional user,please be careful and responsible for the safe operation of the engine at all times. If in the future, your engine is acquired by another enthusiast, we will respectfully ask you to forward this operating manual to the new owner.

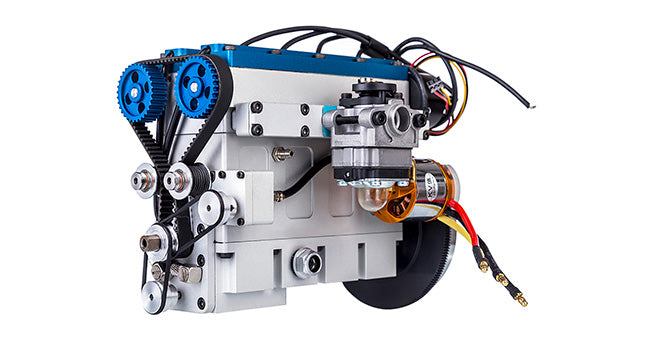

The ratio of the DOHC model engine to the original model is about 1:6, with a built-in oil pump, an external water-cooling pump, and a brushless motor as an electric starter. The dual cam and 8-valve design makes it look more symmetrical.

The water cooling system and independent lubrication system ensure the lubrication of the mechanical structure and long-term operation. The machine adopts a three-piston ring design (including oil ring), which greatly reduces the occurrence of oil burning. The machine supports player modification! If you need one to participate in the competition, it will be a seed of victory!

The machine contains more than 200 parts, do not disassemble under normal circumstances! Since this engine has a large torque and speed, it may cause injury to you during use, please do not disassemble it privately.

Read this manual carefully before using this machine to avoid unnecessary harm to you during the use of this product.

Warning: The following points may involve serious (or fatal under extreme conditions) injuries.

.1 The engine fuel is flammable. Please stay away from open flames, overheating or any place that may cause ignition.

.2 Do not start the machine in a closed space. Because gasoline releases the harmful gas carbon monoxid after burning, starting the machine in an open environment can ensure your safety.

.3 This type of machine generates a lot of heat during operation. When the type of engine is stopped, do not touch any part of the machine with your hands. Especially the exhaust pipe and cylinder of this machine, too high temperature may cause unnecessary burns to your body.

4 The engine fuel is toxic. Please do not let it touch your eyes or mouth. Always store it in a clearly marked container and keep it out of the reach of children.

.5 The model engine will generate considerable heat when it is running. Please do not touch any parts of the engine just after the engine is stopped. Especially the exhaust pipe or cylinder head, improper contact may cause serious burns.

.6 Noise will be generated when the engine starts, please purchase our matching silencer exhaust pipe or run it in an environment far away from residents, because the noise of engine operation may make other people feel annoyed.

.7 For safety reasons, when preparing to start the engine, keep all onlookers (especially children) at least 3 meters away.

.8 This engine is suitable for popular science experiments, model display, model car driving, please do not try to use it for any other purposes beyond the scope of use.

.9 This product is only suitable for users over 18 years of age.

2. PRODUCT GRAPHIC INTRODUCTION

3. BASIC PARAMETERS

Model: D6

Displacement: 36cc

Piston diameter: 22.9mm

Maximum speed: 7800r/min

Fuel: 92#, 95# gasoline (pure gasoline)

Engine oil: 70-80ml oil volume, viscosity above 30w-50

Cooling method: water cooling

Piston ring: 3 rings of simulated engine, including oil ring and cone ring

Shell size specification: about 121*136*60mm

Power: 1.2kw

4. BASIC INTRODUCTION

The D6 model engine adopts a dual-cam four-stroke, four-cylinder and eight-valve design.

An external water-cooled pump can effectively dissipate heat and cool the machine.

The internal engine oil pump, the oil sump contains the oil pump, and the oil is well circulated.

Hall-type cdi pulse electric ignition design, and equipped with a large torque motor starter, start smoothly. Support for retrofitting angle entry igniter!

Production of CNC machining center for the whole shell.

The machine uses pure gasoline as fuel, and has high requirements on the piston,cylinder liner and crankshaft. Its design and production process refer to the original proportion of automobile engine technology. The inner wall of the high-strength cylinder liner is plated with chromium, which increases the wear resistance and smoothness and improves its Service life.

The piston adopts a simulated 3-ring design, including a conical face ring and an oil ring (Zeng's piston ring), which makes the combustion efficiency more efficient.

The crankshaft manufacturer is a manufacturer of automobile engine crankshaft parts. It has 20 years of crankshaft production technology, crankshaft casting parts,dozens of processes, high precision and high strength, to ensure the normal operation of the machine and reduce the failure rate.

5. MACHINE START-UP AND OPERATING INSTRUCTIONS

How to start your machine

1. Before the engine is running, it is necessary to install water-cooling equipment,start the ESC, cdi pulse igniter (distribution mode or automatic angle advance mode),and fuel tank.

Component parameters:

A. Water cooling equipment: ordinary fan water cooling row and water tank are enough, the water cooling row size is not small and 80*80mm, otherwise the cooling effect is not ideal.

B. Starting ESC: 18-24v voltage, current not less than 80A.

C. Cdi pulse igniter: 6-12v, or four-cylinder automatic angle entry igniter.

D. Fuel tank: capacity above 50ml.

2. After the components are installed, add oil and fuel, and add pure water or antifreeze or water-cooled liquid to the water-cooled water tank.

3. Press the carburetor oil bubble (bottom section of the carburetor) to pump fuel into the carburetor until the oil comes out of the carburetor return port, connect the power supply, and prepare to start.

4. Lightly block the air inlet of the carburetor with your fingers, start the motor slowly, so that fuel enters the cylinder, and release your fingers to start the motor with full force.

5. If it fails to start, please refer to the manual for troubleshooting instructions.

6. IMPORTANT NOTICE

Engine precautions

1. It is forbidden to start without adding engine oil!

2. It is forbidden to fill the fuel tank with fuel other than gasoline!

3. It is forbidden to disassemble the machine, otherwise it will not be guaranteed!

4. It is forbidden to touch the pulley and transmission device with your hands when the machine is running!

5. Pay attention to the height of the gasoline in the fuel tank when starting, and the fuel tank outlet should be as level as the carburetor fuel inlet (the difference between the two should not be greater than 2cm).

Startup considerations

1. Start-up environment: engine start will produce fuel exhaust gas, it is recommended to start in a well-ventilated outdoor environment. At the same time, pay attention to the noise that the machine will make to disturb your neighbors.

2. Spark plug: The thread type of the spark plug is M6 1/4-32, and the spark plug is in normal contact with the pulse line.

Note that this machine uses spark plugs, not glow plugs. The working principles of the two are different!

The function of the spark plug is to release the pulse high voltage electricity sent by the high voltage wire, break down the air between the two electrodes of the spark plug, and generate electric spark to ignite the mixed gas in the cylinder.

3. Pulse igniter: Note that the igniter needs to be energized. The ignition system needs to work with the machine distributor, pay attention to the timing of the ignition advance angle.

4. Start the power supply: It is recommended to use an 18-24v power supply with a current above 80A.

5. Starting speed: about 1000 revolutions per minute.

6. Carburetor: Before starting, you need to press the oil bubble to make it full of fuel.

Pay attention to the carburetor clean to prevent clogging.

7. Heat dissipation: The heat dissipation system is sealed and does not leak liquid.

Failure to properly dissipate heat may damage your machine.

8. Pulley: The timing of the machine is designed with an external pulley. Pay attention to cleaning the pulley and belt to prevent foreign matter from entering.

9. Fuel: Fuel is gasoline, pure gasoline is used, do not use mixed gasoline.

The machine fuel is gasoline flammable, which is dangerous, please fill it carefully!

7. REGULAR CLEANING AND MAINTENANCE

How to maintain your machine

In order to use the engine longer and better, users need to clean and maintain it regularly, which can extend the life of the engine. Our company will also provide long-term maintenance services for this product.

1. Change the oil regularly. The running-in period of the new machine is about 50 hours. Please change the oil once.

2. Please add 50ml-70ml to the engine oil. Too little engine oil will cause greater wear and tear of the machine, and too much oil will easily overflow from the crankshaft vent.

3. Carefully clean the remaining dust and oil on the air inlet of the carburetor. The user can install an air filter to ensure the cleanliness of the incoming air. If the carburetor is damaged, please replace it in time. The carburetor cannot be adjusted.

4. The spark plug needs to be checked regularly, please replace it if it is not working properly.

5. Pay attention to the normal operation of the water-cooled equipment, fill with pure water or water-cooled liquid, and the water tank must be in a full water state.

6. Regularly check the important parts of the engine: valve clearance, valve phase,carburetor, timing position, cdi ignition, cylinder pressure, regular inspection and adjustment to ensure that the engine is in good condition.

8. WHAT IF THE ENGINE FAILS TO START NORMALLY

Pay attention to the state of the engine when the machine is difficult to start

1. Check whether the pulse igniter is working normally and whether the battery of the igniter is deficient. If so, please replace the battery. Check whether the spark plug is working properly, if so, please replace the spark plug. Whether the distributor is working properly, follow the 1342 ignition sequence (the one near the "distributor" is

cylinder 1, push it backwards in turn), if it is abnormal, please adjust it to normal.

2. Pay attention to whether the electric motor is running normally, if not, please check the status of the motor and the ESC.

3. Check whether the carburetor is working normally, block the air inlet of the carburetor by hand, start the machine to observe whether the fuel is flowing in the oil pipe, if not, please adjust the carburetor or change the carburetor.If you find that the oil intake is not smooth, you need to check whether the carburetor and the oil intake pipe are blocked. If the carburetor is damaged, you need to replace the carburetor to start. If the oil intake pipe is blocked, you only need to

clean the oil intake pipe. To start.

4. Please adjust the carburetor throttle bolt or change the fuel if the idle speed is unstable. If damaged, replace the carburetor.

5. Observe whether the valve clearance is normal. The valve clearance is normally 0.1-0.2mm. If it is abnormal, please adjust it to the normal state.

6. Rotate the crankshaft by hand to observe whether the pressure in the piston cylinder is normal. If it is abnormal, check the sealing state of the valve and cylinder gasket. If it is abnormal, adjust or replace it.

7. Observe the timing status. In the normal state of each piston cylinder, the first stroke piston top intake valve is completely closed. If it is abnormal, please adjust the camshaft angle.

8. If the machine emits white smoke and is difficult to start, or the machine knocks, it is usually the ignition advance angle failure. The pre-ignition is usually 5-10 degrees between the piston and the crankshaft before the piston is set. Adjust the advance angle to resolve the failure.

9. REPLANCEMENT OF OPERATING PARTS

After long-term operation, the friction between the various parts of the engine will produce wear and the matching clearance will be too large. Replacement of related parts will better maintain the stable operation of the engine. When you are in use, there are situations such as inflexible starting, reduced power, and unstable idling.

Please feedback your use process and poor engine performance to the local dealer, we will serve you wholeheartedly. For the replacement of parts, we will provide professional equipment and an experienced team to complete. Please do not disassemble the engine without professional tools to avoid the risk of uncontrollable

damage to the engine.

10. OUR COMMITMENT

1) Please contact the distributor in your country or location. If you purchase online,you can also obtain.

Obtain all kinds of parts and a full set of services. For detailed information about each part, you can ask the dealer for it.

2) During use, if there are technical or use problems, it is best to provide pictures and videos. We have a professional team online to answer you for free.

3) If your dealer is unable to perform its technical services, we will provide you with technical support directly.

Leave a comment