How To Build V-Twin Engine Gasoline Engine | Enginediy

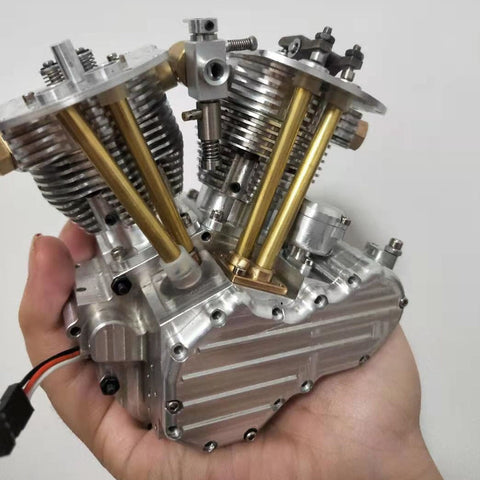

FG-VT9 V-Twin Engine 2 Cylinder 4-Stroke Air-Cooled Gasoline Engine | Enginediy

I came across a Harley-Davidson panhead engine more than 100 years ago on the engine forum in December 2020. The cylinder diameter of the engine is 16.7mm and the stroke is 21mm.

When I first saw this engine, I was deeply attracted by it, so I decided to make my own mini version of V2 engine model based on this engine. I like engines and collect a lot of them. I really enjoy them when they work. state. I searched a lot of information from Google and YouTube, hoping to restore the appearance and keep the simulation level as much as possible, including engine noise, but I did not have a real engine, nor even looked at the physical machine, because it is too old. Perhaps it only exists in the hands of a handful of collectors and it is too difficult to obtain.

In January 2020, I started to build the plan. This is difficult. I can only get engine information from the existing data. I chose a rocker arm design that is different from the panhead engine, and adopted a rocker arm design with a common ohv structure. Yes, it is easy to process, which will shorten my production cycle, I can’t wait.

The engine will all be made by cnc. It has a beautiful and atmospheric appearance. I like to collect it, so I can't bear it in the future because it will become dark due to oxidation. So I will use anodized cylinder surface to keep it bright. At the same time, the rocker cover will be chrome-plated, and the shiny appearance will make my mood better.

I spent a long time, because my job is an engineer, I can only complete my production in my spare time. After 7 months, it was finally completed. I started to try to start, but it failed. Then I started to check the camshaft and found that the angle was wrong. I thought the camshaft angles of the two cylinders were equal, because they were so in my previous engine design experience. Then I simulated the 3d plan, and it seems that my guess is to fight for, and it also needs to add the angle of the ejector rod tilt.

I was about to start trying to start one of the cylinders. I removed the spark plug of the cylinder with the wrong cam so that it would not add resistance to the cylinder that was ready to run. I welded a Hall igniter and tested it. He succeeded. The engine sound is very nice and fascinating.

I rebuilt the cam, contacted my good friend and asked him to make a new cam for me, yes, he used a cutting machine to make the cam.

After I started to assemble the new cam and checked the ignition timing of the two cylinders, I found that if the trigger magnet is placed on the flywheel of the crankshaft, then he will need 2 igniters and 2 Hall triggers, which is not good, etc. I started successfully, I will put him on the already finished distributor.

Astonishing! It started. Next I will optimize it to almost perfect, this is an impressive V2 engine, it is my treasure collection, I am happy to share the construction plan with you, maybe when you see this engine, do you miss the story of more than 100 years?

Autor:

Engineer Mr. Xi

Founder of Cison Engine

Let me show you the processed photos.

Leave a comment